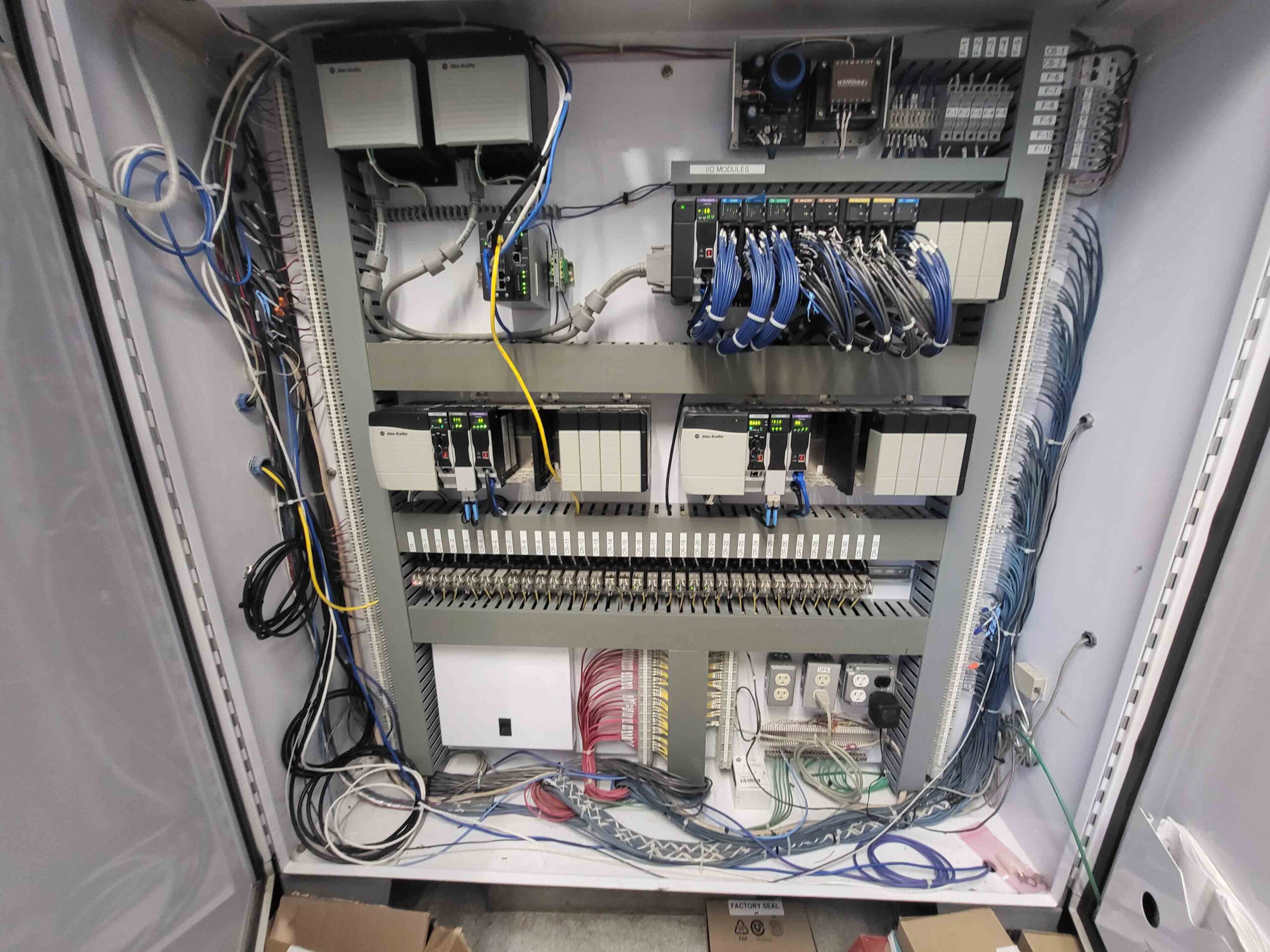

Redundant Rockwell SCADA Upgrade & Modern Ethernet/IP Migration

Municipal Water Treatment Plant

We customized a modern SCADA solution to the plant’s unique configuration, upgrading a legacy redundant system by migrating to Ethernet/IP networking while preserving mission-critical redundancy with the latest Rockwell modules and PLCs. The project incorporated 8 new sensor technologies, modern pumping integration, fixes to 10+ years of dosing and level-control issues, advanced historian archiving, intuitive HMI visualization, automated regulatory reporting, and precise time synchronization for enhanced reliability, compliance, and operational efficiency. This enhanced visibility, reduced manual effort, and positioned the plant for future optimizations like AI dosing.

- Customized SCADA architecture for the plant’s unique configuration, migrating to modern Ethernet/IP networking while preserving and upgrading mission-critical redundancy with the most recent redundant modules and PLCs

- Integrated 8 new sensor technologies and modern pumping systems, resolving 10+ years of dosing and level-control issues for improved accuracy and stability

- Added precise time synchronization and advanced instrumentation for reliable event sequencing and process monitoring

- Implemented FactoryTalk Historian SE for reliable long-term data collection, trending, and analysis of key process variables

- Deployed FactoryTalk View SE HMI for enhanced visualization, intuitive operator control, and real-time alarms

- Integrated XLReporter for automated DEP/environmental regulatory reporting with scheduled, customizable outputs